Our Tenacity and Passion

for the Best Products.

We aim to become a leader in the global automotive market who develops new future technologies

through creative thinking, endless challenges, and innovation in response to the rapidly changing landscape.

We contribute to the technological advancement of the automotive industry by developing new materials

for plastic products, promoting lightweight designs; replacing onboard electronic components with interchangeable modules

to address the rise of electric vehicles; and making exterior panels out of plastic.

Our R&D Achievements

-

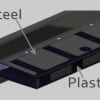

Steel-Plastic Hybrid Parts (2023-2024)

- Features :

- Steel inserts, high-rigidity parts, improved anti-collision system, lightweighting

- Applicable models :

- Prototype developed

-

3D Lighting Grille (2022)

- Features :

- Improved functionality and design aesthetics, communication between vehicles and pedestrians, 3D design

- Applicable models :

- Prototype developed

-

Plastic Fender for Inline Coating (2022)

- Features :

- Plastic fenders instead of steel, available for inline coating (190°C), lightweight prototype

-

Eco-friendly Parts Using Recycled PP Materials (2022)

- Features :

- Improved functionality and design aesthetics, communication between vehicles and pedestrians, 3D design

- Applicable models :

- Prototype developed

-

Plastic-Quarter Glass (2021)

- Features :

- Plastic-quarter glass substitute for glass, improved design flexibility, lightweighting

- Applicable models :

- Prototype developed

-

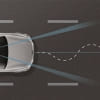

Intelligence Vehicle System (IVS)

- Features :

- Estimated market size of USD 301.1bn in 2019 with AAGR of 36%, preparation for the future increase in autonomous vehicles, with automated controls such as SCC, AEB, LDWS

-

Digital Picking & Bar Code System (2010)

- Features :

- To prevent errors and omissions

-

Lightweight Exterior Parts Using Composite Molding (2010-2011)

- Features :

- Ultra-fine+ counter pressure + core-back molding, lightweighting

- Applicable models :

- Prototype developed

-

Ultra-fine Foam Molding (2002-2005)

- Features :

- Cost reduction, lightweighting, improved productivity

-

Plastic Door Panel (2006-2007)

- Features :

- Cost reduction, lightweighting, improved fuel efficiency, improved design flexibility

-

Plastic Hood (2005-2006)

- Features :

- Cost reduction, lightweighting, improved fuel efficiency, improved design flexibility, compliance with pedestrian safety regulations

- Applicable models :

- Prototype developed

-

Plastic Tailgate (2004-2006)

- Features :

- Cost reduction, lightweighting, improved fuel efficiency, improved design flexibility

- Applicable models :

- Prototype developed

-

Flame Plasma (2003)

- Features :

- Applicable to bumper protection

- Awards :

- Won the Technological Innovation Award (2004), (KAP)

-

Invisible Airbag (Molded Type) (2003)

- Features :

- Cost reduction, improved productivity, lightweighting

- Applicable models :

- CARENS

- Awards :

- KT MARK(2004), NEP(2005)

-

GIM Bumper (1999)

- Features :

- Cost reduction, improved productivity, lightweighting

- Applicable models :

- RIO

- Awards :

- KT MARK(2001)

Design

We implement optimal 3D designs through concept design, package layout, and master section verification

that reflect customer requirements.

Using molding and structural analysis, we create robust designs and perform the entire process

from product design to mold design as a one-stop service to ensure manufacturability from the initial stage,

maximizing productivity, quality, and development efficiency.

-

Concept Design

- Design Planning : Customer requirement analysis, vehicle

package review, design concept determination - Sketching & Layout : Reflecting design concepts, review on package layout and master section

- Basic Structure Review : Rigidity, collision safety, and lightweighting

- Design Planning : Customer requirement analysis, vehicle

-

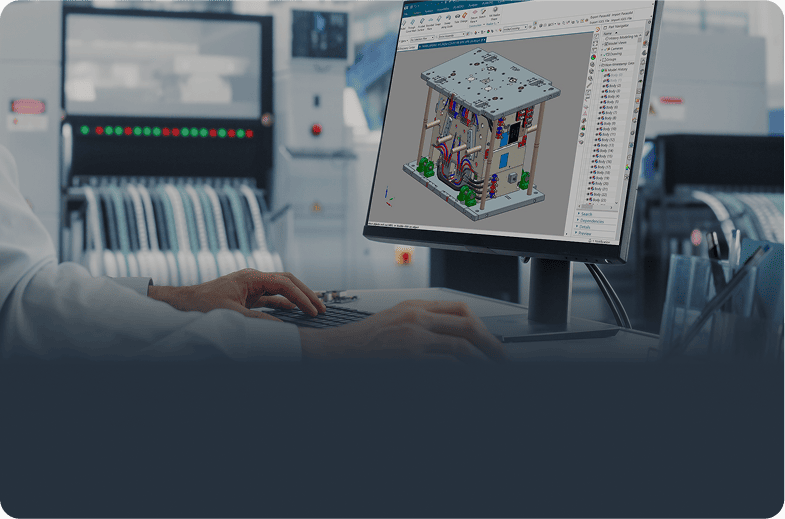

3D Design and Modeling

- Digital Design : 3D CAD modeling, shape/dimension review

- Structural Verification : Application of robust design using molding analysis and structural analysis

- Mass Production Availability : Review on process and assembly, design optimization

-

Mold Design

- Preliminary Review : Review on mass production of molds considering quality and productivity

- Mold Fabrication : Design, manufacturing, and production of mass production molds

-

Design Optimization and Verification

- Design Improvement : Risk management and improvement based on DFMEA and DV/PV testing

- Design Optimization : Performance improvement through analysis-based adjustment of design parameters with structural and functional optimization

- Quality Assurance : Design review, modification management using PLM systems

Molding Analysis

We optimize every step of injection molding using precise analysis technology to ensure high-quality products.

Based on the analytic results, we improve product quality and maximize the efficiency of molds and processes

to provide optimized solutions tailored to customer requirements.

-

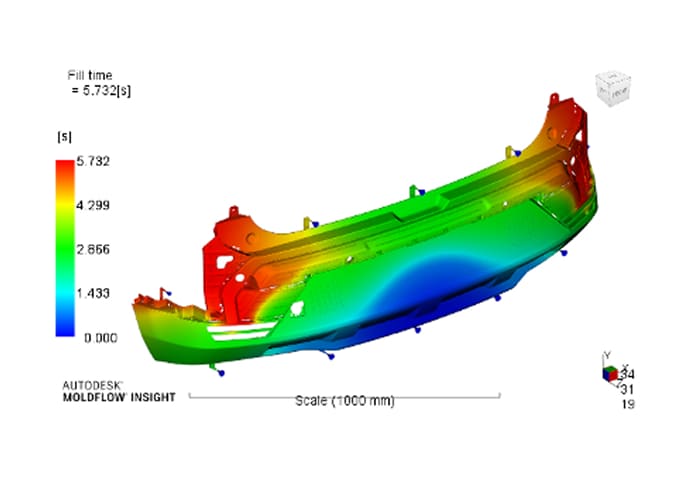

Flow Analysis

We analyze the process of filling cavities with resin to predict and prevent problems such as flow imbalance, weld lines, bubbles, and step-outs.

This ensures uniform appearance and strength, and we design the optimal gate position and resin flow to improve the molding stability of products. -

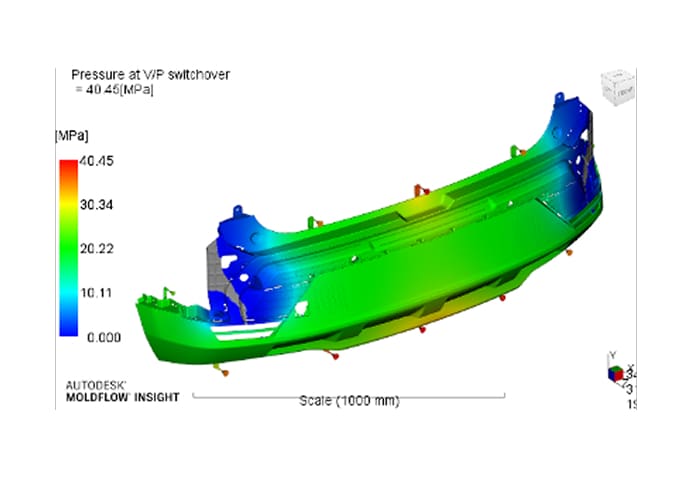

Packing Analysis

We analyze volume shrinkage and internal stress during the packing phase after injection to minimize flash and sink marks.

We set appropriate packing conditions to optimize mold clamping force and pressure, ensuring dimensional stability and maintaining consistent product quality. -

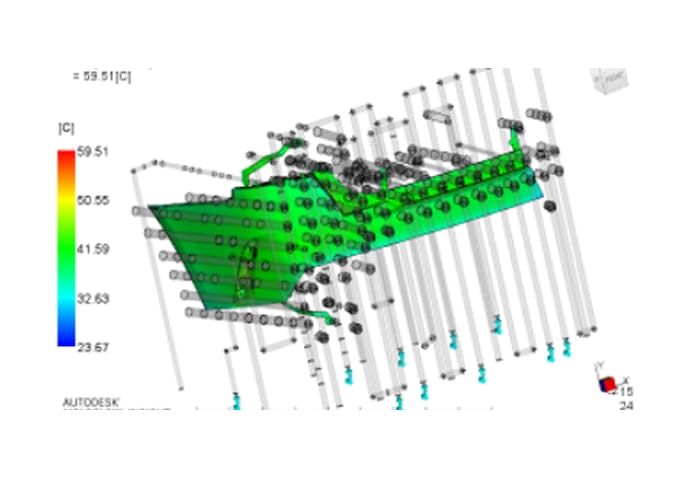

Cooling Analysis

We analyze the cooling phase, which takes the most time in injection molding, to maximize cooling efficiency.

We apply optimal cooling lines and baffle designs to minimize temperature variation, shorten cycle times, and increase productivity. We prevent deformation caused by uneven cooling in advance to improve product precision. -

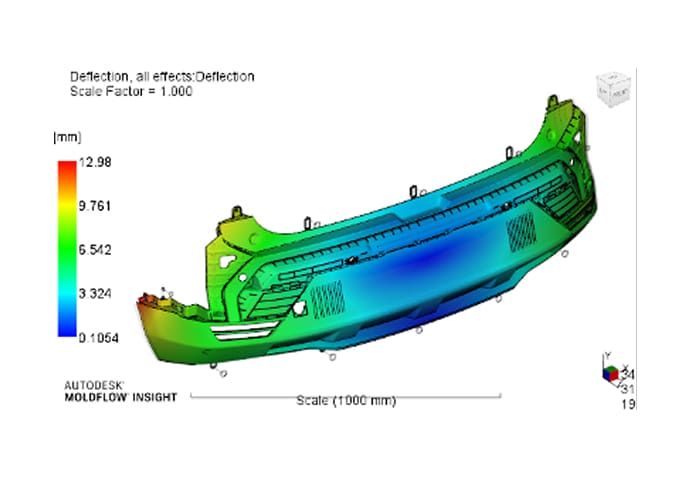

Warpage Analysis

We predictively minimize product warping and shrinkage after molding to ensure dimensional accuracy.

With the precise analysis, we control deformation factors from the product design stage to deliver high-quality molded products and solutions optimized to customer requirements.

Structural Analysis

Based on precise structural analysis, we optimize strength, rigidity, fatigue life, and thermal deformation to maximize product

durability and performance. We aim for optimal designs that ensure stability and achieve lightweighting and cost reduction.

-

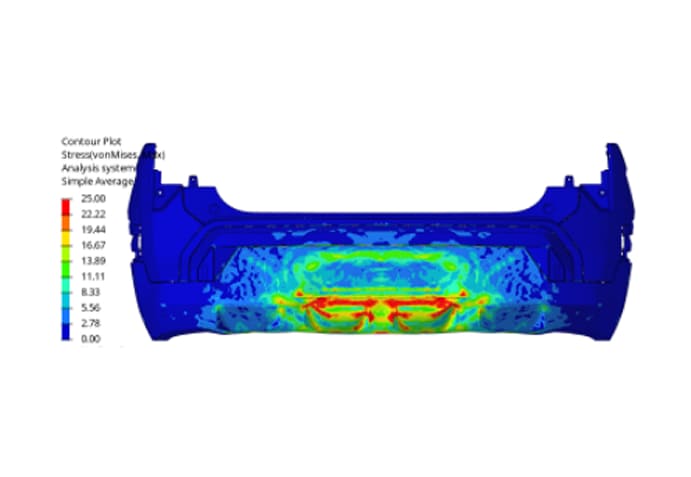

Bumper Impact Analysis

Linear analysis and optimal design are performed to ensure low-speed collision safety of bumpers.

We perform pendulum tests at collision speeds of 4.25 KPH and 2.6 KPH to meet regulatory and customer requirements, and precisely analyze impact energy absorption and deformation behavior.

Collision analysis improves bumper durability, minimizes damage, and optimizes restoration performance to ensure design reliability prior to actual vehicle testing. -

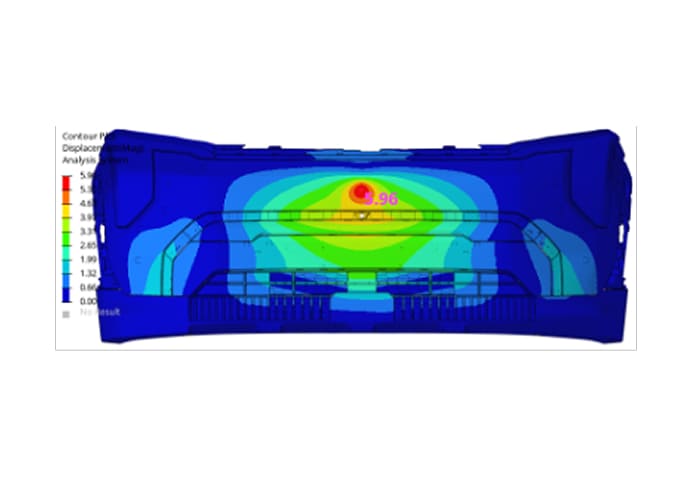

Stiffness Analysis

Deformation analysis is performed under external forces of 10 to 15 kgf to ensure structural stability and product quality.

Factors potentially reducing rigidity are analyzed in advance, and optimal designs are applied to minimize deformation and improve durability, thereby enhancing product reliability. -

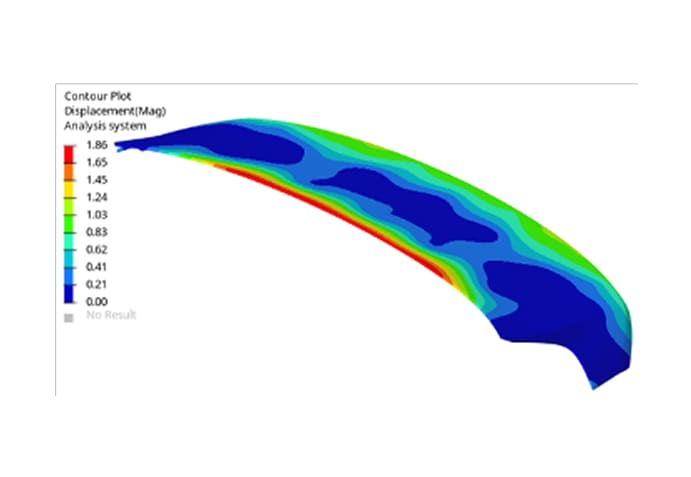

Thermal Deformation Analysis

We analyze the deformation behavior of products in high- and low-temperature environments to perform thermal deformation analysis.

Based on this analysis, Plakor makes design improvements to ensure minimized deformation, stable appearance quality, and further reliability. -

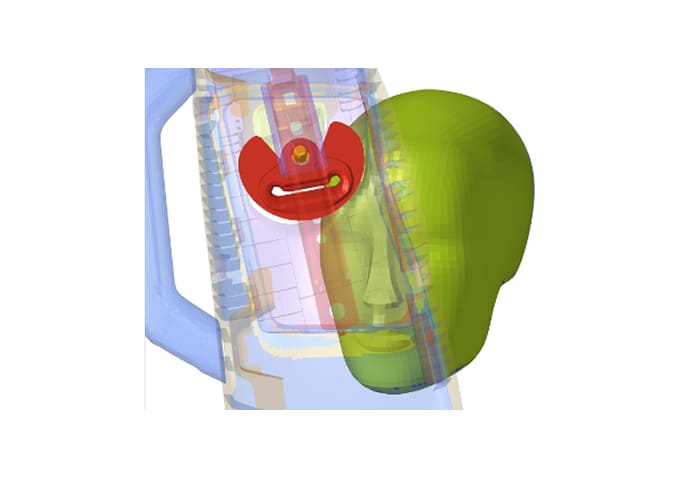

Free Motion Headform Impact Analysis

FMH analysis is used to evaluate occupant protection and analyze head injury criteria (HIC) in the event of a collision. Impact mitigation structures are optimized to apply designs that meet regulations and safety standards and improve pedestrian safety.

In particular, the analysis is performed to meet North American FMVSS 201 performance requirements to implement designs that comply with global safety standards.